Military Jeep Restoration

Jeep Restoration.

A few years ago my son and I traded into a bunch of WWII jeeps and

partial chassis. We kept the best three. He needed a summer project so

I turned him loose with his buddys to build one jeep from all the

available

parts. That went pretty well and he ended up with this '45 Ford GPW

which we have taken on many trips over the last five years.

I ended up with a '43 Willis MB which wasn't too hard to get

running. (Overhaul of transmission, transfer case, drive shafts, engine

lower end, replacement of more or less everything under the hood,

brakes, fuel system and a bunch of assorted wires, springs, shocks:

"the usual" I was to

later find out.) I started a military oriented repair / restoration

awhile afterwards with a goal of never having my jeep apart too long at

one time. The third jeep, a '45 Ford, was sold to a friend who took it

entirely apart for a "frame off" OEM correct restoration. It has been

apart for a couple of years (in 2005) and is about 3/4 done.

This photo was on a trip to see the start of the

Rubicon trail north of Pollick Pines in California. We've

run both ends of that trail several miles

in but never done the middle (yet).

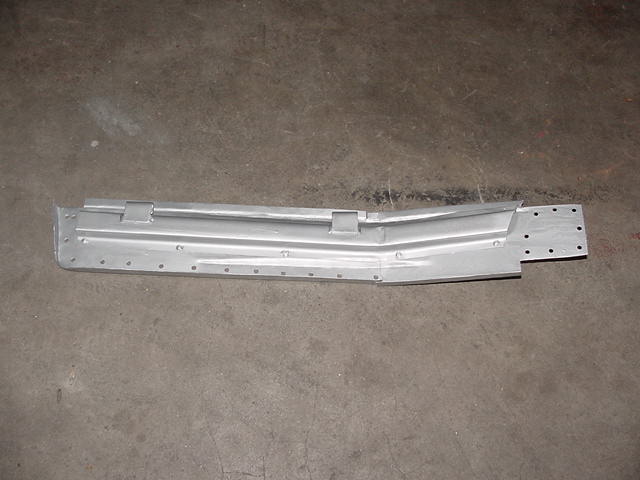

Somebody welded a flat panel without reinforcement or correct features

into the jeeps rear body and made a channel iron bumper over the top of

a ruined rear cross member. It is a common type of repair if your not

concerned about originality. I make NO claim to being a body man or

painter but this seemed so necessary to fix I cut it out and found

the floor was wrinkled up. I usually don't do much restoration work for

myself because I'm busy machining or doing customers cars. However I

ordered a new OEM style panel and cross member and then found that

everything on the back of the jeep was incorrect or broken in some way

while doing research to fit the panel properly. Stretching the floor

back to semi flat and pressing the tool compartments sort of square

again was a reasonable but "not perfect" repair.

That effort turned out well so I started working my way around the

drivers side. The fuel tank well was rotted out and lower body side

rusted so I cut it out to reach sound metal. The cross member was also

cracked and rotten so a section of that was removed also.

I fabricated new metal to surround a replacement gas tank well and fit

those parts to the opening. Weldable primer and a combination of spot,

MIG, and torch welding enabled a satisfactory attachment to the

original body and allowed a replacement fuel tank to be installed with

it's related seals.

This area started looking better so I replaced the left side foot step

and floor

braces when I welded in the side panel I'd fabricated. Then all the

brackets, holes, and accessories had to be researched, located, and fit.

Because I wanted to use the jeep occasionally after the panels were

structurally finished I painted the area OD Green. Then various

holes were located, then drilled, and accessories were fit. Finish body

work was performed to this area several months after this photo was

taken.

Along the way my seat frames needed attention and several gas

tank

/ seat bottom combinations were trial fit to center the gas filler

correctly. Reproduction parts from several countrys and craftsmen

created fitting tolerance issues that prevented easy removal of the gas

cap. I eventually achieved a slightly better fit than shown here using

a tank from Mike's Military Motors (made by his Australian buddy) and

an

MD Juan bottom on an original frame. It's not perfect, but is nearly as

good as parts available will allow.

This project was getting interesting and fun because I'd

joined the

Military Vehicles

Collector Club of California (MVCC) with my son and the friend

who was restoring

one of the jeeps we'd sold. We

had also met several parts vendors and many club members who helped us

learn what we were trying to do. Ron's G503 web site is a "must view" area. I've

found there

are many shades of early OD green from various suppliers.

At this stage anything "green" is OK because I determined the

whole tub

will need to be re stripped and properly anti rust

treated before being entirely repainted.

This project was getting interesting and fun because I'd

joined the

Military Vehicles

Collector Club of California (MVCC) with my son and the friend

who was restoring

one of the jeeps we'd sold. We

had also met several parts vendors and many club members who helped us

learn what we were trying to do. Ron's G503 web site is a "must view" area. I've

found there

are many shades of early OD green from various suppliers.

At this stage anything "green" is OK because I determined the

whole tub

will need to be re stripped and properly anti rust

treated before being entirely repainted.

After trial fitting five shovels, three axes, a couple of ax handle

brackets and bending the jeeps side those accessories began to

fit. All the seat cushion holes had to be welded shut and re drilled.

I wanted to do the windshield next, then the hood, to continue

working systematically around the jeep. Each part had problems with

corrosion, extra holes, prior repairs, paint build up, and bending.

These parts were sandblasted first and then all prior repairs were cut

out to be redone. The outer frame tubes were straightened and sleeved

internally. The lower sheet metal panel was crack repaired and had

extensive welding to fill holes created by after market spotlights. The

inner frame was so corroded it required epoxy filler to recast the

glass channel in addition to welding and hardware replacement. The

rifle holder was a week project by itself once correct rivets and

padding were obtained.An electric wiper was discarded and period

correct vacuum wipers were put into place.Once all the sub assemblies

were repaired and painted I installed my old glass in the inner frame

because slight bubbling and age discoloring in the laminate edges

looked very appropriate. The whole windshield fit to the jeep with new

snaps for a OEM style canvas top.

My hood hinge required several new

segments be handmade. Various holes were welded shut and ground smooth

before assembling with new fasteners, stop blocks, and a maintenance

guide holder. These repairs turned out well, on par with other club

restored jeeps. The windshield, hood, and cowl took about a month to

do, plus some time for the wipers and rifle holder.

One

step along the way with a Jeep restoration is looking for original

"Hood Numbers" or determining them. A place to look is at a hoods

edge when preparing for paint work. I carefully sanded each paint layer

looking to see if something remained of the original marks. In this

case nothing was evident. The layers were (going from metal out) gray

primer, Marine corp blue/green, Forest Service Green, fire truck red,

OD Green, Yellow, OD Green. Dents made it a bit confusing.

One

step along the way with a Jeep restoration is looking for original

"Hood Numbers" or determining them. A place to look is at a hoods

edge when preparing for paint work. I carefully sanded each paint layer

looking to see if something remained of the original marks. In this

case nothing was evident. The layers were (going from metal out) gray

primer, Marine corp blue/green, Forest Service Green, fire truck red,

OD Green, Yellow, OD Green. Dents made it a bit confusing.

The white paint on the jeeps cowl is a mystery. Has anyone seen this

before? It looked like a sign background located under the red layer?

Most of this work was done prior to 2006. This year front bumper and

tow bar parts have been procured and some original gauges are being

rebuilt for the dash area. It is a turning point because taking the

front sheet metal apart is more than a couple of week job but doing

work to the dash area opens up all sorts of electrical loom issues.

This is a fun project. Jeeps are about as simple a vehicle as ever

built and very well documented. Parts are available at many quality and

price levels and personal preference for various finished

configurations is quite normal. While I strictly repeat, I am not a

body and paint guy, all the work done to this vehicle

represents my personal efforts except stitching canvas components and

overhaul of the vacuum wiper motors.

April 2012. An update is long over due for this story and project.

The three jeeps have each had considerable work completed. Gary, our

family friend who bought the first '45 Ford finished his restoration.

It is nice from front to back and has been shown at several MVCC meets

since completion in 2009. Daryl bought an aluminum "Arctic Top"

for his from the M38 series very similar to the one shown in Fred

Crismon's book "All American Wonder" volume III pages 321 & 323. We

used it off and on for a few years then his interests changed to

motorcycles and his BMW M3 so it was parked until 2011 when he sold it

(less the top) to an East Coast buyer who did a complete restoration.

It turned out to be a match numbers and tub vehicle so was well worth

their efforts to make it like new again. My jeep, the '43 Willis, took

a side step because I became excited about participating in the

transcontential military convoy of 2009 and began planning

modifications which would allow easier travel at higher speeds. I made

some wide "combat rim" wheels for fitting 7.50 tires from a new set of

reproduction rims similar to ones mentioned in various historical

texts. I obtained a T-90 transmission and big shaft transfer case also.

However I broke a valve spring in 2008 so I disassembled part of my

engine for a "quick fix". I found it worn out past the point of an

easy repair so continued to strip it "in frame" for an overhaul. Then I

measured my jeep's block standard bores and upon finding .060 taper and

worn out valve guides paused, thought about many engine parameters I

knew could be improved, then gathered a few blocks and heads to test

changes for increased power before I re-machined mine.

That testing and computer modeling work led me to design and have

fabricated connecting rods and pistons of much more modern design which

are lighter, stronger, more efficient and capable of withstanding at

least 3 times the power levels of a stock engine and twice the RPM.

Then I figured out a "drop in" 11/32 bronze valve guide & big valve

conversion kit from industrial engine turbo charged diesel parts. These

are also far stronger, lighter, and better in all ways than stock

replacement parts. This assured me I could, with better airflow

and block strength dramatically improve power output. I next turned my

attention to cylinder head options and obtained samples of all military

versions of the 134 cid heads and one of a vintage after market "hot

rod" style for analysis. This lead me to some opinions about gaskets

and fit, which I believe will end in having custom head gaskets made

because modern gaskets don't fit original casting very well, and

original gaskets are not made from very good materials. I also did

a lot of air flow testing and found the engine quite well balanced in

its stock form. That means to improve output significantly the intake

air path and carburetion will have to be improved generally. The

exhaust manifold is fine, so far. There are also limitations on

camshaft lift which need to be watched carefully in relation to head

milling for compression ratio increases because air flow drops off if

camshaft lift brings the valves more or less than .035 away from

the head. The next step in this process is to dummy fit and port some

passages to determine if separation of the intake runners is needed.

Then I'll be able to fit all the bits of data together and plan a

logical block and manifold modification process. While this work was

ongoing the transcontential military convoy of 2009 successfully

concluded. I reset my timetable to participate in the Aug 30 2012

MVPA ALCAN Highway Convoy but that looks doubtful

because August is only a few months away at this point.

Back to Fowler

Main page