| Cadillac Seville | MG Kit Car | Jensen Interceptor | Two '60's Studebakers | 1965 Corvette |

| 1965 El Camino |

BMW cars | 1965 Pontiac GTO | Jeep |

!967 Corvette |

|

|

||

|

Hi power and auxiliary lighting was added by Bill. The car was refinished and detailed by Cadillac before returning to daily service. Now; more than 50,000 miles later Bill is still excited when he drives his car. It is smooth, quick, and quiet. |

|

Jim had wanted a replica MG kit car for a number of years. Then his son located one in Utah. The vehicle was shipped to California before a thorough inspection. I discovered this MG had a worn Chevette drive train and suspension. Fowler Automotive repaired the front suspension and revised the rear suspension. Various items in the drive train were reworked. Installing a California legal emission system was needed for certification. A fuel cell with rollover protection was installed. |

||

|

|

This is a 1974 Jensen Interceptor. It went through several owners until coming into Bob's ownership. Bob likes British cars and has Jaguar and Aston Martin cars in his stable. This one had been disassembled mechanically over a few years time and the parts scattered into various storage locations; both in and outdoors .... Some were left here at my shop by the former owner; who started out to repair a damaged and overheating engine, which is how I met Bob. He wanted to find all the parts and see if there was a possibility of putting a vehicle back together. Well; with enough work anything is possible. Bob took about a year to gather things up and do preliminary cleaning and evaluation. I started on the Chrysler 440 Cid engine and finished it about 8 or 9 months later. I changed it to Keith Black pistons and quench style combustion chambers, installed a revised camshaft from Hughes Engines ( http://www.hughesengines.com/ ) and complementary valve train parts from Competition Cams. We lightened the rods and crank as part of generally rebuilding and updating the already stout power plant. MoPar had a great manifold and a few other items we needed that took forever to special order but were worth the wait. Meanwhile Bob was arranging for the transmission and other accessories to be rebuilt and doing interior and body chores. A shop in Los Gatos installed the engine and did a lot of under hood head scratching and parts locating to produce a "drivable under its own power" chassis. Then we got serious about assembling a car. I did some under hood detailing, built an oversize mandrel bent exhaust system and re-plumbed the fuel and emission systems. Bob continued on the interior and accessories until he was ready to drive the car to a specialty shop in Washington state to have the wooden dash and console veneer replaced and the air conditioning restored. He returned a few weeks later a happy man. This car gives a new meaning to the concept of high speed cruising. Effortless, understated, solid, comfortable for hours behind the wheel driving is what this car is all about. It can also chirp the tires into second gear and hit 80 mph in a city block which is a bit mind boggling for a vehicle that weights nearly as much as a Chevrolet Suburban. It turned in a bit better than 17 mpg on the Washington run. Now Bob is looking for a few bits of trim, a great radio, and more open roads.

These are a pair of Studebaker vehicles. The one on the left is Annette's Lark sedan and the truck is Hans '64 half ton. Both have V-8 power and have been driven almost daily for several decades. I started working for Hans and his wife when he was too busy or needed professional help repairing the Lark. Beginning in 1969 or '70 and continuing to the present I have rebuilt it's engine in 1975 and again in 1996. The Pickup came into Hans garage about 1968 and I did a few things for him to it over the years eventually rebuilding the mechanics of the vehicle and engine in 1997. Both engines required odd sized parts here and there and conversion for unleaded fuel. Both have a bit more compression than stock and a bit of head porting. A local shop, Dunn's Autobody, reworked the truck's body, floor panels, and paint. Hans has done most of his own service work over the years and really loves these cars. They are both quite original. Between them they represent nearly a half million miles of driving and customer satisfaction.

I guess everyone who has been working on cars for awhile has done a few Corvettes. This 1965 Convertible is one of several I take care of and has given a lot of pleasure to Don who bought it in 1966. I started servicing it in 1969. He drives it almost every day, and has steadfastly refused to give it to his adult children. About five years ago we figured he had more than 600,000 miles on the odometer. His car started out as a 365 HP 327 with a 4 speed but that engine assembly was swapped out and taken as a "core" on it's first rebuild by another shop a long time ago. Presently it is powered by a 327 of about 300 HP using World S/R heads and a mild GM cam I built for him in 1987. It was balanced, blueprinted, and the compression height carefully set. Don has worn out 3 or 4 engines, had the transmission and rear end rebuilt twice and the suspension overhauled more or less 4 times. I've put an interior in it a couple of times and done most of the mechanical repairs of any consequence except the differential and trailing arms. Herlinger Corvette Repair takes care of those sub assemblies. Several shops have done general maintenance or body repairs and paint over the years. In the last ten years we have started to put the car back to a more "original" configuration. Little things that have gotten lost or broken are becoming more important and the correctness of replacement parts is being given more effort. But make no mistake, this is no garage queen. Any day Don wants to see people or do business he twists the key and the pipes rumble to life. His car is a driver and I bet Don will keep it that way.

European

headlights were a thoughtful project as the cars wiring needed several

diodes added to various circuits to prevent cross feeds between high,

low, driving and turn indicator lights. He was well on

his way to creating a track car when he hit a tree "checking tire

clearance" after an M series five lug wheel / Koni suspension

conversion using E39 5 series sport wheels with 235-45R 17

tires. This required moving the foot well sheet metal back and rolling

his fender lips, modifying his brake cooling ducts for E30 M3 brakes,

and hand

made brake backing plates. Hardened bushing were also needed to keep

suspension component deflection under control. The car had great grip

and handling but

accidents happen real fast when cornering speeds start going up

and road hazards stay the same width.... which is why I generally

don't

do a lot of suspension work for young street racers. I think a "track

car" should be on the track and a driver should go to a real drivers

school sooner rather than later.....

European

headlights were a thoughtful project as the cars wiring needed several

diodes added to various circuits to prevent cross feeds between high,

low, driving and turn indicator lights. He was well on

his way to creating a track car when he hit a tree "checking tire

clearance" after an M series five lug wheel / Koni suspension

conversion using E39 5 series sport wheels with 235-45R 17

tires. This required moving the foot well sheet metal back and rolling

his fender lips, modifying his brake cooling ducts for E30 M3 brakes,

and hand

made brake backing plates. Hardened bushing were also needed to keep

suspension component deflection under control. The car had great grip

and handling but

accidents happen real fast when cornering speeds start going up

and road hazards stay the same width.... which is why I generally

don't

do a lot of suspension work for young street racers. I think a "track

car" should be on the track and a driver should go to a real drivers

school sooner rather than later.....

Custom

pistons .003 oversize were jointly designed by ourselves and Brian

Nutter at Wiseco to take advantage of a thin medium tension ring pack

and light weight forging mold used by VW in their formula one engines.

It also enabled "saving" nearly perfect cylinder bores by just very

modest honing. Internal thermal barrier coating was sent out to Replica

Machina and external powder coating was sent to Spray Technology. A

custom gauge set was installed in the area below his radio indicating

oil and fuel pressure. We completed his car just in time for Daryl to

shower and grab a fresh shirt before driving to Beamer Feast 2007.

Since then Daryl figured out an extensive electronics entertainment,

communication, GPS upgrade then gathered and installed the components

in a hand made custom system without detracting from the M3's original

dashboard or interior design significantly. He's also driven about

15,000 miles so at his last oil change we switched the engine to Mobile

I oil in preparation for another Thunder Hill practice session. His

story takes a twist here because we'd bought a '96 328 sports coupe as

a project car a few month prior. It had been in a minor front end

collision and taken apart at a body shop. Then the estimate got out of

control as the owner's insurance company declined coverage. It needed

new front sheet metal, some general repairs other shops had missed or

done incorrectly and normal service work. However all the work was just

nuts and bolts after we had a few parts painted. Even fixing the ABS

pump wasn't too bad. The hard part was getting little hardware and trim

totally correct.

Custom

pistons .003 oversize were jointly designed by ourselves and Brian

Nutter at Wiseco to take advantage of a thin medium tension ring pack

and light weight forging mold used by VW in their formula one engines.

It also enabled "saving" nearly perfect cylinder bores by just very

modest honing. Internal thermal barrier coating was sent out to Replica

Machina and external powder coating was sent to Spray Technology. A

custom gauge set was installed in the area below his radio indicating

oil and fuel pressure. We completed his car just in time for Daryl to

shower and grab a fresh shirt before driving to Beamer Feast 2007.

Since then Daryl figured out an extensive electronics entertainment,

communication, GPS upgrade then gathered and installed the components

in a hand made custom system without detracting from the M3's original

dashboard or interior design significantly. He's also driven about

15,000 miles so at his last oil change we switched the engine to Mobile

I oil in preparation for another Thunder Hill practice session. His

story takes a twist here because we'd bought a '96 328 sports coupe as

a project car a few month prior. It had been in a minor front end

collision and taken apart at a body shop. Then the estimate got out of

control as the owner's insurance company declined coverage. It needed

new front sheet metal, some general repairs other shops had missed or

done incorrectly and normal service work. However all the work was just

nuts and bolts after we had a few parts painted. Even fixing the ABS

pump wasn't too bad. The hard part was getting little hardware and trim

totally correct.

1965 Pontiac GTO. This is a car I wish I had more photos of as it evolved. I bought it the summer I graduated from High School. It was a bone stock 389Cid 4bbl, 4 speed convertible in perfect shape so I immediately started to change it around for better road performance. Somehow I missed the fact it would make a better Drag Racer than Road Race vehicle because my friends were running Corvettes', Camaros', and a Boss 302 Mustang in SCCA production modified classes in the early 1970's.

I lowered the car, tried many different shock, spring, sway bar combinations, performed various engine modifications, made a front disc brake conversion and boxed my rear control arms and many other modifications popular at the time including headers and what amounted to 4 inch open exhaust pipes.. I learned a lot about what works and what doesn't.I eventually got it to run about one second behind my friends Boss 302 (who had factory backing from Ford) and about two seconds behind the Corvettes on the same track on the same day. Cooling was an issue so I cut the radiator support to install OEM heavy duty cooling sheet metal to hold an optional radiator core. I also added an engine oil cooler from the aircraft shop with aircraft hose assemblies, a common source for those items in the early 70's. Corvette rims and secondhand Goodyear Blue Streak racing tires were my only wheel options because of a "college kid" and "working nights" budget.

I started to "restore" my GTO in the early 1980's after modifying it through the '70's. It was originally light blue which I had changed to Corvette racing green with a silver stripe. I changed color again to Corvette maroon with a gold stripe when the C-3's came out. A friend did minor body work and disassembled the car. A couple of years later we had a professional shoot paint in a rented booth and we put it back together again. Then I stored it for about 15 years until my children were grown. A few parts got "robbed" for my '71 Chevelle stock car along the way, but a 12 bolt rear end with a Moroso brute strength carrier was "donated" back so I guess it worked out about even. I wanted to install a new interior, refinish a bunch of chrome parts, and fix my radio and rally gauges but the roll bar was a bigger problem. I'd discarded my back seat because it interfered. I eventually found another one, but it took almost another 10 years to find time to modify it so the roll bar and seat back both would fit together.

I know a lot more about fabrication now than when I first built

my GTO so I cut out and rebuilt the roll bar and

heavily modified my seat frames. I put back sound

deadening material I'd thrown away and got new

padding for everything, including under the

dashboard.While I'm not an interior specialist I did get a

very nice result by doing this job one part at a time. When the frames

were ready for upholstery I had Bob at Mountain View Auto Interior

install OEM front covers (he's done my convertible tops for years and

"normal" work) and took my car to my cousins shop in Ukiah, CA. for the

custom stuff. We worked together to modify OEM style rear covers and

make roll bar padding sleeves. It only took a couple of days to finish

assembling the interior from that point.

Additional gauges are fuel pressure, oil temperature, and a factory vacuum gauge on the console.

1965 El Camino This is

Hank's vehicle. I believe he bought it five or six years ago, after

seeing it at a car show, from a fellow in the East Bay part of the San

Francisco, CA area. Hank likes cars generally and has a taste for older

British models but wanted this El Camino mostly for fun while having

some utility for doing short distance hauling jobs. The El Camino is an

original 327 cid 350 hp car with a power glide and got a 3.36 ratio 12

bolt limited slip rear end at some point. It is an original P/S, P/B,

A/C car. It was a "restored car" meaning repaired and modified but

still having

the correct engine and transmission and suited for daily use.

It had a few rough edges I fixed for him over a couple of years time.

The power glide column shifter needed a total rebuild. The disc brake

conversion was plumbed incorrectly and pulled left whenever the

brakes were applied. His drive shaft was bent and various leaks and

electrical issues needed correction but over all it was a nice car to

have bought.

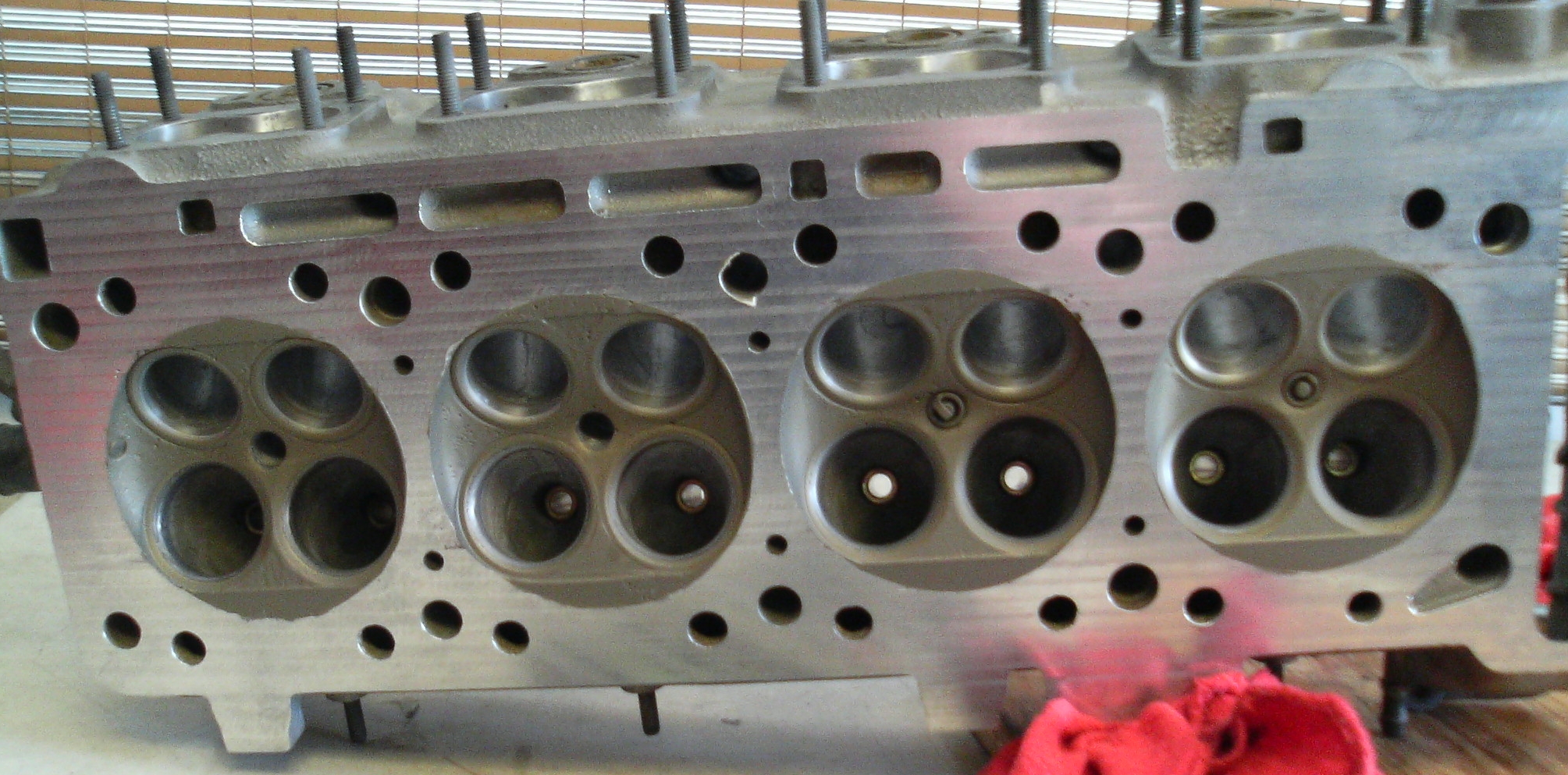

The engine had been rebuilt but it didn't last too long before

spinning a rod bearing and then started to lock up. We discussed

under hood repairs and ended up taking it all apart for a second "high

performance" rebuild. To preserve the original numbers and date codes I

saved his block and heads. Because the 327 cid crank was shot I had a

350 cid crank ground to fit the small journal block main bearings. Then

I lightened, profiled, and reduced it's rotating diameter before

sending it out for nitrite hardening and finish grinding. I switched

rods and pistons to create a light weight 350 cid engine with a windage

tray, crank scraper, and anti slosh baffles all contained within a

"stock" oil pan. I ported the "Camel Hump" small valve heads a lot,

then worked Hank's intake manifold, spacer block combination, and air

cleaner for maximum flow.

I wanted this engine to produce all the torque it could to overcome Hank's tall differential gears and two speed transmission, but felt it couldn't stand the very high compression ratio and pressures produced by his small combustion chambers. So I used flat top pistons and had Dema Elgin grind a special cam with delayed intake valve closing to reduce dynamic compression pressures. Deck height, gasket thickness, quench clearance and hand fit ring end gaps were all carefully preplanned. High quality timing components and roller high ratio rockers with poly locks, screw in studs and guide plates were all reworked to fit under stock sheet metal covers. Bill Long of Bill's Transmission Service, Sacramento, CA. and I rebuilt Hank's power glide and added a mild shift kit. I rebuilt everything else under the hood as well, nothing fancy, just clean craftsmanship with mostly stock parts. In the end the engines compression ratio of 10.25 to one was just too much for pump gas once the heads started flowing air, even at modest throttle openings. The engine's timing had to be retarded 15 degrees and the idle speed became unstable.Because the fuel situation wasn't getting any better over the last year we recently switched the car to a mix of race gas and premium fuel to obtain an octane rating above 100. What a difference. With essentially a stock ignition advance curve it pulls really hard from start to noticeably more than a maximum top indicated120 mph. It is just the ticket for short distance hauling now.