This IMCA modified has run at San Jose, Watsonville, Antioch, Petaluma, and most recently at Merced Speedway in the Central Valley of California. Fowler Automotive has been involved with the car over seven racing seasons providing engine service originally; and in the last five , complete assemblies. Jim Pennington is the car owner and has chosen to run an all-Ford drive train based on a Windsor 351 CID block. Cleveland heads are substantially reworked as are the much longer connecting rods. At various times Fowler Automotive also provided shop space for weigh-in adjustments and wheel alignment. In 1997 the car won several heat races, a main event, and lead many laps. It almost always finished in the top five or spun out while leading... the team had a new driver that year, Brett Montana. In 1998 we again had several new drivers, Galen Carrera, who ran mini sprints at north bay tracks in prior years. Daren Pennington who had raced dirt Karts with some success, and John Kirkpatrick who wanted to move up from entry level stock cars. For 1999 John Kirkpatrick drove (rookie year). He finished 8th at Merced and 19th in the five state IMCA Western Region. In 23 starts I believe he won more heats than any other driver at Merced, three trophy dashes and had a 3rd place as his best finish. In 2000 the car was stored pending a sale that never materialized. For the 2001 season Jim Pennington drove for fun as his time and finances allowed. The sponsors of Jim Pennington Racing are Blossom Valley UNOCAL and Fowler Automotive. Central Tools in Sunnyvale, Monsters of Rock, Bradley Nameplate of Fremont CA, and Custom Alignment of Mtn. View CA. helped out in prior years. Ray Jacobson at Tuban Industrial Products, Mtn. View has provided invaluable help with the Ford combination. Bill Jones of Taylorsville Utah and Kelly Owen of Santa Clara were great technical advisers.

Jim Pennington was president of X-act Computer Service located in

Sunnyvale until his passing in 2003. My understanding is the car was

sold several years later and it's spare engines were sold separately. I

have some parts and build / tech specifications for them if the new

owners need service.

Hayos Racing

Hayos Racing has been running a Toyota Truck in various configurations for many years.They have won several regional championships and gained considerable respect for fair and even handed competition. Their teams history can be followed at Hayos Motor sports I started helping their team with technical questions in 2003 regarding their 22 R based race engine and some tuning issues. That lead to further involvement until in 2006 the truck was switched to a V-6 engine based off a 5V-FE Toyota product converted to racing use by a prominent north Bay Area shop. That engine was rebuilt in my shop to reverse engineer it's secrets, document it's parts list, and prove it's horsepower. It was later dyno tuned in Fremont CA to re-set up the fuel injection management system. That engine powered the truck at the Terrible Herbst SCORE race in 2007 where their team ran in 4th place until overturning on a triple jump which accident injured Patty Hayos the trucks driver.

She has recovered and the truck is being rebuilt for the 2008 season.

Part of that effort is overhauling the 5V-FE engine again because it sustained minor damage from running upside down. That was done in my shop and installation was done at the Hayos Racing facility. It is presently being run for testing and practice on a track in the Prairie City Off Road Park in central California. Several additional Toyota engines have been obtained for modification and development at Fowler Automotive because this platform has a lot of room to make more power. At least two more chassis are being built by the Hayos team and the teams future looks promising.

Vintage Mini Cooper race car & Ladd Fowler engine and car builder biographic sketch

Greg Jones

Managing Editor, Engine Builder<http://www.enginebuildermag.com/>

gjones@babcox.com<mailto:gjones@babcox.com>

(330) 670-1234 x272

3550 Embassy Parkway

Akron, OH 44333

Good

evening Greg, I’ll put my response

to your questions in blue. I’ve metaphorically

tossed you a majority of

whole baby’s story, including its blanket and buggy. Ladd

* Can you give me some background

information

about

yourself? How did you get into the industry/engine building?

I’ve

been a mechanic since I was

very young, 7-8 years old. Back then my dad gave me a go kart fitted

for a

Briggs & Stratton lawn mower engine which I had to swap on and off

his

mover to ride the kart. I always had access to his hand tools to make

things and

a few years later when I was 12 he gave me a set of welding torches.

That led

real fast to building two stroke mini bikes running McCulloch engines

which

were flat out dangerous – I’d chase down DT1 Yamaha

motorcycles in the Santa

Cruz Mountains pretty successfully. I’d heard a story that the

mark of a true

master mechanic was being able to do things blindfolded so I taught

myself how

to build the McCulloch 91 – 101 engines blindfolded when I was a

freshman in

High School. I also rebuilt every one of our family car engines with my

Dad –

Buicks and Cadillacs - between late grade school to college years.

By

then my older buddies and I

had motorcycles and cars which we worked on after school when we

didn’t have

jobs to attend to. By the end of my junior year I was maintaining a

dairy

processing plant three days a week because I was nearly the only one at

that

business who (intuitively) understood their pasteurizing and bottling

equipment. Eventually I became one of the youngest licensed processing

plant

operators in the state, getting my license at age 18 under the tutelage

of a

state inspector. And a few afternoons a week I worked for a lumber and

supply

company fixing trucks. I was also fixing

cars for people who somehow found out I could do that when I was not

working

elsewhere.

This

gave me a chance to know

our local auto parts supplier well. They had a machine shop in back of

the

store which fascinated me because I had constant need for industrial

and

automotive parts and machine made or repaired pieces. Somehow I

graduated High

School as a “C” student. Looking back that is amazing

because I never did any

homework or read assignments. I also missed many classes when called in

to work

early.

In

my

senior year one of my

buddies had a neighbor who was racing Mini Cooper “S” cars

and Corvettes in

SCCA autocross events with some success. He bought a Mini Cooper to

repair to

be like his neighbor. Occasionally I helped my buddy convert it to

“S”

specification by swapping performance parts into it. Because I was the

guy who

had a torch set we used that to heat-then-beat his firewall in for

carburetor

clearance. It was the first car I ever caught on fire. We put most of

the fire

out pretty quickly, but it continued smoldering for hours under the

dashboard.

I

had

bought a ’65 Pontiac GTO

by then because my mother forbid me to buy a Corvette saying they were

too

dangerous. Looking back that was actually a pretty funny turning point.

The GTO

didn’t stop, couldn’t turn, and had more power than many

Corvettes. It was the

more dangerous car which shortcomings I initially proceeded to amplify,

not understanding

even more power would make it handle worse faster. Some other friends

were autocrossing

a Boss 302 Mustang with OEM support, various Corvettes, and Z-28

Camaros so I

tagged along with my GTO. I believe I was 7th in the county

one year

running in the SCCA “H production modified” class, about a

second behind the

Camaros and 2 seconds behind the Corvettes. I was rebuilding my

Pontiac’s

engine almost monthly because I couldn’t get good timing chains.

And I didn’t

understand valve train geometry that changed because of various

cylinder head

swaps until a bit later on. When Cloyes came out with double roller

chain models

and some hot rod magazine did an article about checking valve to rocker

arm

contact points my engines started to run better and longer. I also

began to

learn about chassis set up trying to make that GTO corner like a

Corvette.

But

my

buddy and I drifted apart

after High School so I didn’t work on a Mini Cooper again until a

couple of

years ago. I mostly worked with other

vehicles, some of which became known as “muscle cars”, and

repairing machinery

and equipment.

In

1972 I started what eventually

became my small automotive repair business. And I continued to seek out

opportunities to gain further education to validate what I was

attempting to

do.

I

attended Foothill College majoring

in business administration but that was very hard for me. The scale of

business

size discussed in class started with a few hundred employees but I

wanted to

learn about proprietorships and partnerships with a few guys. After two

years

of agony I switched to De Anza College majoring in their auto

technology

program, then graduated 2nd in my class. At graduation I was recruited

by the

auto parts store I was doing business with to be a machinist in their 3

man back

room shop. After a year the business owner opened a second location and

I was

offered that stores machine shop as a solo gig. But

I quit on good terms despite my love for

machining to go east for what became an office job running finances and

managing a fleet of 65 cars scattered throughout the New England

States. After

a couple of years of freezing winters and shocking eye opening

experiences with

rusted out near new cars I came back to sunny California to more

formally open

“Fowler Automotive” in 1976. It was an easy economic

decision despite being

asked to return to work by business owners of every job I’d ever

held. I could

make in a day in my own shop what took a week to earn as an employee.

So I

serviced those businesses as an independent contractor while gaining a

few more

dedicated clients whose families I served, in some cases, for three

generations

before I retired a couple of years ago.

* Can you give me some background about Fowler Automotive? When did it

start?

What does the shop specialize in? Do you work on an assortment of

engines and

applications? Is it a full machine shop? Do you do everything in-house?

Fowler

Automotive has been a

sole proprietorship since 1977. It was formed as a home based service

business

with a somewhat backwards business plan. I have done a very broad

variety of

automotive and equipment related services for a small select client

group for

the last forty-five years. For their various needs and interests

I’ve cared for

everything from small rototillers to long haul diesel trucks with a few

boats,

motorhomes, and an airplane tossed in. Some of that work was strictly

economic

business - to get something working again so it could generate profits.

Some

has been recreational to enable their various trips, movie shoots, or

competition / restoration projects. And a majority of it was in-between

those

categories where I was providing ordinary repair service for their

family

vehicles. Over those years I accumulated equipment and tools to meet

their

needs as I went along.

Along

that path I’ve been

invited to and attended GM school, Ford Industrial Engine School and

countless

clinics or manufactures training sessions. I sought out an opportunity

to

attend Cummins Engine School. I went back to college at night to

formally learn

welding skills and non-destructive testing processes.

I

was

lucky to trade Joe

Mondello an intake manifold resurfacing fixture I invented then

patented for

attendance at his engine and head porting schools. Bill Jones of

Taylorsville

Utah took time from his life to teach me a lot about head porting and

air flow

from a practical perspective. I’ve been tutored by Allan Lockheed

and Dema

Elgin in advanced engine design and competition engine preparation over

many

years’ time. I’ve had significant passing acquaintance with

several really

great leaders in fields of business ethics and industry procedures who

mentored

me as I helped them. I was among the first technicians to be tested and

awarded

ASE “Master Mechanic” and “Master Machinist”

certificates. I kept both those

ratings current until a couple of years ago. Becoming and staying

educated in

my industry is central to the success I’ve had meeting a diverse

range of

client requirements.

In

the

1980’s I was doing a lot

of Corvette repair and service as Fowler Automotive in conjunction with

another

friend’s business; Herlinger Corvette Repair. I also ran an entry

level stock

car under NASCAR rules in the Winston West series. I did well as an

owner /

rooky driver finishing tenth place out of over 250 cars registered to

run in

the area. But I didn’t have time to build my own engines despite

having

education and training to do that. So I hired it out. When my engine

builder

became ill with cancer I bought his home and automotive machine shop to

enable

continuing service for my clients, and then helped care for him until

his

passing. After his passing I sold my stock car then sponsored out of

that

machine shop, over the next twenty years in small ways, TrueSpec Racing

who ran

Chevrolet engines in various dirt track venues, Pennington #9 Racing

who ran Ford

Clevor engines in IMCA modified events, and Hayos Motorsports, an off

road

truck team running Toyota engines.

I

have

used a simple rule of

thumb for business equipment acquisition. If it will pay for itself in

a few

jobs I’ll acquire it or establish a working relationship to use

it. I have come

to understand a business principal – you don’t need to own

everything for a

“full shop” but you do need to have knowledge of where and

how all those

machines work and how to gain essentially immediate access to them when

needed.

A growing problem which now confronts service providers like me is many

of our

vendors and affiliated shops are closing so their inventory and

equipment

disappears which makes it far harder to actually create new automotive

race

cars, hot rods, or restore vintage vehicles.

A

bit

more than a decade ago I

was diagnosed with leukemia and have been in and out of experimental

chemotherapy since. A few years ago my automotive vehicle / fabrication

shop

was zoned out of existence after being in that location for more than

35 years.

But I was able to keep my automotive machine shop which was in the next

town, mostly

for hobby shop interests. I still own a lot of metal fabrication

equipment and

traditional industrial machine tools, most of which have gone into

“semi-storage”

circumstances.

As

Fowler Automotive I have been

“the kid” in a circle of older car guys who owned

businesses I ran with. Many

of whom were far more talented than I. Many of them have passed on. I

am now

semi-retired and specialize in doing fun things with my remaining

clients, who

have become friends and buddies. We do projects; like building this

Mini Cooper

to win the Nationals. For us, fun projects seem to attract more fun

projects so

we are considering getting another building, to both gather our

collective

equipment into one place and consolidate more of our labor into one

spot. But

the financial implications of doing that in the Silicon Valley simply

don’t

make sense. So we may fade away like so many other shops have done.

* Layand Engine – How did the engine get to the shop, is this

from a repeat

customer or new customer?

This British Leyland engine came into

my shop from a

client I’d built a 1966 Mustang for. His wife wanted a V-8

automatic

transmission light blue with white interior Pony Pack convertible. I

built them

one from a brown on brown car that sat oddly and too high, which turned

out to

be full of hidden body damage. I saved the front clip, cowl, floors,

and trunk

lid to build them a car from that, in cooperation with a body shop.

When he

wanted to go racing he bought a Mini Cooper to relive and extend his

college

experiences driving that marque from days when they were new. Because

he was so

pleased how that Mustang turned out I was invited to straighten out the

Mini

Cooper after he had some bad experiences in other specialty shops.

* What was wrong with the engine/reason it was there?

This

Mini Cooper was a beautiful

show car semi-converted to be an autocross play car. After being

purchased by

my client we took it to Thunderhill Race Track in Northern California

for an

open track test day with other clients of mine who were running their

cars. It

drove ok and showed promise of becoming really fun. It was the first

Mini I

ever drove. He decided to send his Mini to two nationally prominent

Mini Cooper

shops for “road race” preparation and various upgrades.

Then

the car owner took it to

Sonoma Raceway for an event after spending many thousands of dollars

where he

experienced multiple significant vehicle failures. He called me to the

track so

I could trouble shoot his vehicle where I found issues with ignition,

carburetion, charging, cooling, and engine valve train interference.

There were

also fluid leaks, and generally poor assembly which taken all together

prevented his Mini Cooper from making an entire lap under its own

power.

I

fixed what I could in the Pits

with generous help from other racers in his class – remember;

I’d not worked on

a Mini Cooper since high school – almost 50 years previous

– so I had to take a

moment with a knee on the ground with it, so to speak, then another

moment to get

my brain to see what my eyes were looking at. I was able to get his car

to run

a couple of places in front of being last by the end of his event

program.

The

car was returned to the

building shops for “warranty service” where it was fitted

with a new transmission,

more engine upgrades, swapped its Weber carburetion set up for

SU’s, received

an alternator, and so on. He felt confused by this, especially when it

broke

the new transmission on his next outing vs. the turnaround he had seen

under my

care. So I was hired to fix the car and act as crew chief for his next

season,

after it was again returned to the other shops for a replacement

transmission.

Because

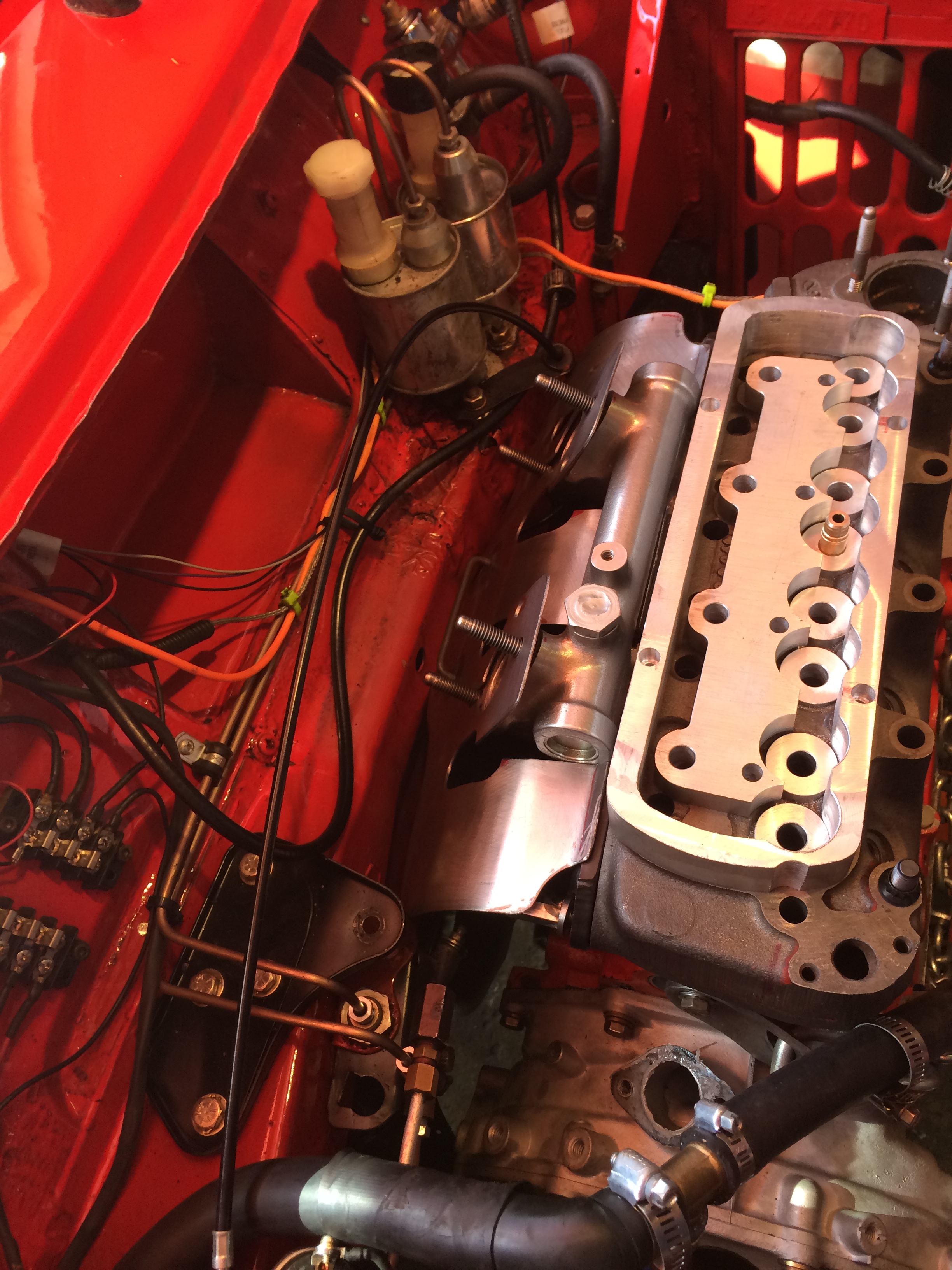

the Mini Cooper engine

crankcase also houses the transmission and differential while sharing a

common

oil system it is very hard to talk about just the engine, because, if

some part

of that system fails it usually wipes out everything else too. Pictured is my client’s crankcase assembly

ready to receive his modified race engine.

Because

the Mini Cooper

driveline is so short and suspension so closely coupled, any suspension

or

driveline vibration or failure can affect the final drive inside the

engine

crankcase, which can then damage the engine.

* What application is the engine for? Does the Mini Cooper get raced,

or was

this just for a restoration project?

This

Mini Cooper project started

out as a vintage road race effort on a “hobby” basis. After

a couple of events

I had his car running mid pack, about 6 seconds off the leaders at

Sonoma and

Laguna Seca tracks.

This

is a dangerous position to

be in because other cars can hit you when you are in the middle of

things. We

were discussing improvements to his car which would allow it to move

into

running with more capable cars and drivers when he was lightly kissed

by

another car whose driver turned right in a left hand corner rubbing our

Mini

Cooper in its left rear fender arch. Our damage was near zero, 10

seconds with

buffing wax took the rub mark off and a washer under the screw head of

the Mini’s

plastic wheel arch molding fixed that. However, in my opinion, the

driver who

caused contact between the cars complained so effectively about

“over

aggressive driving” he got my client and himself suspended for a

year. We were

shocked at the ruling, but within a couple of months figured we’d

use that time

to rebuild the Mini Cooper correcting fundamental issues and making

upgrades.

It was a turning point away from “restoration” towards

“race car”.

* What kind of work did you have to do on the engine? Machine work to

the block

or other parts? Other adjustments, etc.?

To

gain 6 seconds lap time vs.

the leaders we deliberately analyzed options open to us within class

rules and

known parts we could buy. Modifications were planned by study of

“A+” series

engine existing art and published articles, then by my client’s

sense as a

driver of what he needed to go faster. The engine rules for our vintage

class

dictated a non-roller rocker arm assembly be used and

visually period correct appearance of the

engine. We had to use SU carburetors and could not modify the engine

compartment sheet metal (for more velocity stack clearance) past what

was done

on original “S” model vehicles.

In

this case engine work started

with another transmission gear set which had dog gear shifting pawls.

We

calculated a 2 second per lap gain was likely because of quicker

shifting speed

and having better ratio selections. We also felt replacement of the

differential with a Quaff torque biasing unit would extend engine and

tire

life. Conventional traction lock and posi-traction clutching

differentials shed

materials into their oil supply, which in this engine are then fed into

the

engine bearings. We had excessive wheel spin in corners that was

melting our

tires which we felt could be better controlled.

Opening

the crankcase for gear

replacement would lead to inspection of the engine’s condition,

which had

excessive pressure indicating poor ring sealing.

Replacement

of the gear sets

would also allow replacement of both axle assemblies with lighter,

stronger,

smoother running shafts thereby increasing power available to the

wheels, and

reliability. In my opinion running stock Mini Cooper drive shafts above

90 mph

is insane. A broken driveshaft might strike the oil sump knocking a

hole which

will cause engine failure, a fire, and perhaps a wreck. Our Mini needed

to exceed

110 mph to win; therefore we needed upgraded drive shafts.

Swiftune

provided 10 spline

Hardy joints from Spicer with shafts and yokes to match. But they were

not

shipped with a grease seal and packing nut despite having a grease

nipple for

lubrication. If installed as shipped they would toss grease directly

onto the

headers causing a fire hazard. Swiftune, when called, said

“nobody runs the

grease seal or nut so we don’t send them out that way”. And

then said they

could not supply them. Our local Spicer dealer could sell us new

(identical)

yokes with the seal and nut preinstalled so we bought them, robbed

their seals

onto the Swiftune parts, and saved the extra forged sections for spare

parts.

There

was a second minor issue

with Swiftune supplied output flanges. The Quaff differential, on the

RH side,

would not allow its flange to seat fully into the differential where a

snap

ring would retain it. This was not discovered until the car was pitted

after

qualifying laps in the 2017 Canadian / American Challenge race weekend.

The

yoke had walked out of the case introducing a vibration into the

driveline. A

quick trackside fix was to put a hose clamp on the axle which retained

the

yoke. A permanent solution done later on was to machine about .075 off

the yoke

which allowed it to seat fully.

To

gain more seconds on leading

cars my client’s engine would have to rev higher. Virtually all

Mini Coopers

that road race in various divisions of vintage stock class use one size

of

Hoosier tire. It is the only one available. To gain top speed, and

because

final drive ratios are essentially limited to the one you build an

engine with,

the engine itself needed modification to run faster. Virtually all

historical

wisdom, and both professional Mini building shops in our area indicated

limiting RPM to under 6500 - 7000 would delay crankshaft failure for a

season

or more vs. failure within a couple of events if run faster. To run

“up front”

we needed to increase engine speed above 8000 RPM which meant

engineering for

9000 RPM to create some safety for over-speeding incidents. To gain

that

increase in engine speed virtually every part of the engine needed

modification, including the induction and exhaust systems.

* What parts did you use in the engine?

Please let me know

the specific part and manufacturer – block, cylinder heads, rods,

pistons,

crank, camshaft, bearings, gaskets, valve train, etc. Do you prefer a

certain brand

of oil?

Despite

having a new OEM

crankshaft in an “A+” series block running new upgraded

rods and pistons we

retired those parts in favor of a dedicated DC5-2 racing lightweight

rotating

assembly from Swiftune in Europe. They recommend against using a

harmonic

damper, which in my opinion is utter foolishness. We used a Fortech

FOR098

racing damper. We also bought Swiftune’s “Feather

Light” lightweight clutch,

upgraded drop gears, pistons, bearings, double row timing chain, and

electronic

distributor assemblies. I believe they also marketed the dog gear

transmission

kit and differential by Quaff. We had a “Longman” C-AHT221

cylinder head, fully

worked to current racing configuration, but determined we needed to

retire it

also, in favor of one ported a bit differently. I made a new head based

off

casting #12G940. We bought a Swiftune camshaft and tappet set with cam

bearings

to suit our intended road racing use. Virtually all smaller parts like

thrust

washers, fasteners, and gaskets came from Mini Mania and Seven Mini

Parts. All

three companies, as vendors, are quite good at having everything needed

in

stock for immediate shipment.

Computer modeling software from Rapid Line and

Performance Trends was used to influence many aspects of our decision

making.

I’ve used both programs for many years and upgraded both for this

project to

their newest “Pro” versions.

I

made

an informal poll of most

Mini Cooper owners at a couple of events we attended in 2016 regarding

engine

oil. Most teams were running Redline 50w synthetic oil without any

problems at

between 75 to 90 psi. At that time we were also, which I felt was an

area for

some testing and possible improvement.

* Did you hit any road blocks with this build, or did it go together

fairly smoothly?

Our

troubles started with this

build almost immediately. Nearly every engine part and subassembly

needed rework

help except the actual crankshaft and rods. By contrast the

transmission and

final drive kits were straight forward and nearly flawless. In the

transmission

only reverse gear needed a small bit of “grinding love”

with an abrasive wheel and

a couple of thin shims to assure clean disengagement.

Beginning

with the premise of

“trust nothing and nobody” I sent the Swiftune #SW2307

camshaft to Elgin cams

to be reverse engineered. While Swiftune provided some data about it,

until any

cam is fully profiled and checked you don’t really have

sufficient data to

computer model engine designs that may use it.

We

discovered the camshaft provided

was much closer to a hot street car / autocross design instead of the

full on

road race cam we requested. We also discovered 6cc dish pistons

provided in the

Swiftune kit would drop our compression ratio from mid-13’s

typical for Mini

Cooper racing engines probability into the low 11’s or mid-10

range, depending

on what head we eventually used. That led to two decisions. First

we’d live

with a compression ratio loss by having a custom cam made which

re-timed the

intake valve closing. And second we would optimize a new camshaft

design to

current state of the art technology with air flow data from a fresh

head build

up. Instructions to Dema Elgin were eventually simple: “grind the

tallest lobe

you can, onto the best blank you can, to obtain the most aggressive

timing that

won’t roll off a Ford tappet”. He understood that perfectly

having designed BMC

cams for winning engines and other companies, or authors, for decades.

As I discussed this with a long time hot rod,

race car, and engine building friend, Gary Hubback, we tumbled onto

noticing

the BMC bucket tappet (photo on right) looked a lot like a Ford Le Mans

427cid

engine part Gary had bought from Hollman / Moody then run in his record

holding

drag car in the late 1960’s (in photo on Left). He still had most

of an NOS set

securely under his workbench which allowed us to take direct

measurements vs.

BMC tappets.

We

did

Rockwell testing with

Swiftune, Mini Mania, ATP (David Vizard’s old company), and Ford

parts to determine

which tappets would be the hardest (Ford). If we bored the BMC block

tappet

holes from .811 to suit the Ford .875 tappets Dema could put a more

aggressive

lobe onto a new BMC blank. Because of the way internal cam journal webs

are

cast in the block to support the cam, upsizing larger than .875 tappets

would

become very hard to do. And would require a custom “fatter”

or welded up

camshaft blank to gain any advantage in profile selection.

Boring

BMC tappet holes required

being able to reach nearly a foot into the block (from collet to tool

tip) and

machining a nearly blind hole at the correct 2 degree inboard

inclination from the

cylinder bore centerline. At the top of a BMC “A+” engine

tappet bore is a hole

about 3/8 inch in diameter intersecting an oil return galley within

about a

quarter inch. The pushrod passes upward through the hole and galley to

the head

inclined inboard to meet the rocker arm shaft, while oil returning from

the

head drips down into the tappet from the galley. Oil

dripping down also fills each tappet

bucket and seeps out of a hole in the side of the tappet body

lubricating it.

The pushrod is about 1/4 inch diameter, solid cast steel, and

isn’t very strong

or stable at higher loads or speeds. That whole system is very iffy in

my

opinion and needs modification for high speed operation. One

modification made

was adding a second tappet drain hole. Shown here the tappets have been

anti

friction coated and drilled. They are racked and ready to clean. At

this point

we had 11 candidate tappets remaining of which I chose the best 8 to

install in

this engine.

Once the engine is running each tappet gains

about 30+ grams of oil weight which isn’t any good. Think of the

camshaft load

running 8 hydraulic pumps jetting oil back up the tappet bore into the

drain

galley through that small hole which is essentially plugged up by the

pushrod.

I

made

tooling similar to a BHJ Lifter-Tru

set, but suited to the BMC blind hole block. In the photo, starting on

the left

side, are two adaptor rings to locate a centering bar into cam bearing

bores.

In the central photo area is the centering round stock bar which has a

hole

pattern bored into it matching the blocks tappet holes. It locates two

dowel

pins into existing or re-bored tappet holes establishing a centerline

and axes

for machine work. In the photo, right of center are two dowel pins with

different sized ends allowing all combinations of bored and un-bored

tappet

holes to be located. They jam in tappet holes, locking the bar into a

correct

position for the next hole to be machined. Photo lower center is a lock

ring

which bolts to the blocks front surface double locking the bar from any

movement after the dowel pins are removed to insert cutting tooling.

Finishing

off the tool set, but not shown, is a precision drill and reamer. Also;

for

final sizing a custom lapping rod is used. It fits into the dowel pin

centering

holes in the locating bar which holds it very steady and at the correct

position in the same collet used to oversize the tappet hole. I also

made a

special tappet which has a scribe point exactly in its center for

marking a

line in the camshaft blank verifying correct location.

Then

I

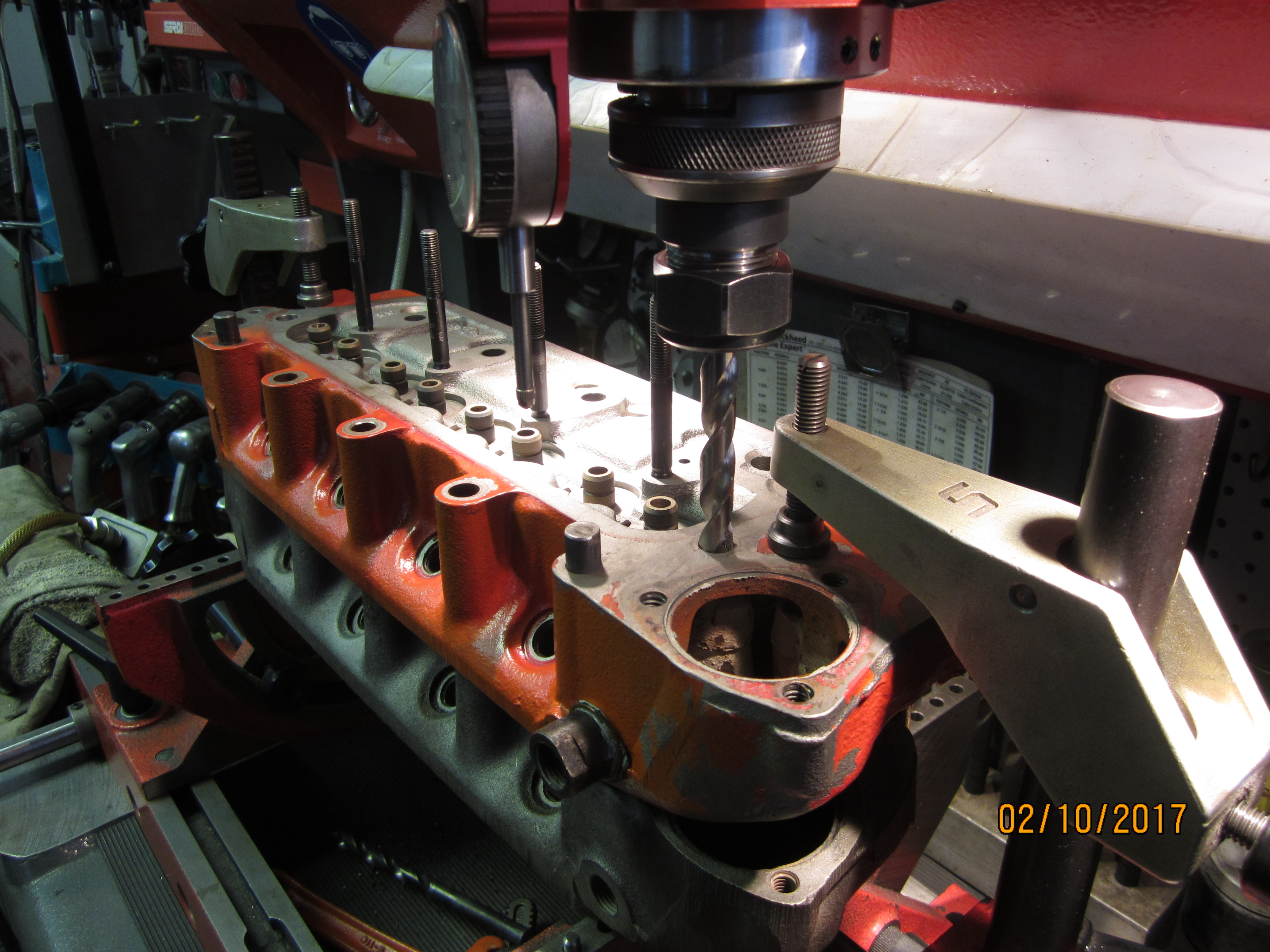

re-bored the tappet holes

entirely into the intersecting oil galley eliminating restriction

possibly

caused by pushrod and tappet pumping motions. I used my Serdi seat and

guide

machine to do the boring job because this 1275cc BMC block (bored to

1310cc) is

so small you can treat it like a cylinder head in many fixturing

considerations. Traversing the air float head of my Serdi machine in

conjunction with my tooling is faster than setting up then moving a

milling

machine table. Chip removal from the nearly blind hole while machining

was done

by vacuum suction out the little oil galley hole. If chips are allowed

to rise

up the drill’s helix they can scar a newly made tappet bore

deeper than the

reamer or hone can remove. This is a tricky bit of machine work,

especially

finish lapping to size and then honing. The tappets are select fit to

their

bores in final engine assembly.

And

after drawing a blue print

of the BMC block’s cam area “as made” I found its

existing tappet bores were

only approximately offset equally from cam lobe centerlines. This

indicated

non-rotating tappet issues might happen. I corrected my tooling to more

accurately place each tappet against the cam lobe across the cams

length with a

proper offset to allow for rotation when ground to the appropriate

taper.

The

next major challenge with

the block is moving its pushrod holes inboard and oversizing them to

7/16th for

tubular 5/16th inch custom pushrods supplied by Smith

Brothers. The

hole needs to be moved, on its 2 degree inclination, measured at the

top, about

.080 or more over about a 6 inch depth. Shown in the photo below is an

initial

set up where pushrod holes are first drilled oversize to 7/16th. Then I

made a

tool change to a very long milling cutter which moved the hole over.

The

aluminum bar was a “straight edge” which located my tooling

parallel to the

crankshaft centerline while being angled inward from the cylinder

centerline.

Installing the drill upside down into the hole and collet helps better

locate

the Serdi machine air float head because my ground rod center finding

tool was

AWOL somewhere else in my shop that day.

This necessary machine work resulted in

breaking into the water jacket on 3 of the 8 holes. Casting shift

seemed to

favor the front holes and thin out the rear ones. Fixing those

perforations

required drilling 3/4 inch holes in the blocks cylinder deck adjacent

to the

pushrod hole. Then sandblasting the water jacket to bare roughed up

metal,

forming thin sheet metal “patch plates” over the areas,

then epoxy cementing them

into place using wire spider legs to restrain movement over night while

curing

took place. Greased wooden dowel pins preserved the oversize pushrod

hole from

filling with excess epoxy. Then I had to plug the deck without creating

a need

to re-machine it. The existing compression height of block decking done

in

other shops had left no material for service repairs. Dressing off

square drive

pipe plugs was done with a hand file and large diamond lap stone after

rough

grinding the bulk of extra metal plug away.

The

next block machining operation

was dowel pinning the head to the block and correcting head stud

engagement

length. The head could move on the block’s ARP stud shoulders

more than the

thickness of its gasket fire ring (Mini Mania Turbo Metro gasket

#STR1057) and

could bring its oversized valves into possible contact with the block

cylinder

walls. Therefore to assure consistent assembly location 2 hollow dowel

pins

were installed around the end studs. The dowels were lathe turned from

steel

stock. The centering tool (photo left side) was made to fit onto a

valve guide

top trimming cutter. The cutter was repurposed to machine out counter

bores to

hold the dowels. Not shown is a sandwich die to allow the valve guide

trimming

cutter to enlarge two complementary head gasket stud holes so the head

gasket,

head, and block would all register together.

I found the head stud holes, after deck milling

by the other machine shops, only had 5-7 threads remaining in the block

so they

needed to be deepened and re-tapped allowing an HSA11-B ARP stud kit to

engage fully

8 threads deep. This was also the time to add a head stud hole to the

new head.

Passenger service BMC engines didn’t need a head bolt near the

water outlet but

racing Mini Coopers did. The BMC Factory added one stud to that area

and it has

become a standard operation to drill any head used for competition in

the same

location as the factory did. I did that

by pattern drilling through a head that had the hole already in it.

They simply

needed to be stacked up, doweled together so they remained indexed

while

machined, and a long drill passed through.

Enlargement

to 1/4 inch of all

oil passageways going to the head, including machining an oil transfer

slot in

the forward cam bearing and around the camshaft journal was done. Do

not cut

away the “dam” between an existing axial oil channel and

new radial one. You

want extra oil to go up to the head not out the front of the engine. Adding a couple of missing threaded holes

which attach the oil pump body to the block was eventually done as

well.

With significant additions, remaining block

preparations more or less followed David Visard’s book and

standard race engine

practice.

This

is the set up I use to

degree camshafts. One dial indicator resolving to .0001 is set up on a

deck

bridge to monitor TDC. A second dial is on the intake lobe pushrod

resolving to

.001 and a third indicator is on the exhaust lobe pushrod resolving to

.001.

That makes figuring out overlap timing very easy. You can just watch

the dials

and move pointed magnets on the timing wheel to stick on any degree

location

you want to count from. I have black magnets for intake and red for

exhaust. Those

basic tools came from PowerHouse (Comp Cams) many years ago and since

then were

extensively modified to become more versatile. The dial indicators came

from Peacock

and Mitutoyo. The front pulley supplied with our Swiftune DC5-2

crankshaft was

re-machined to become a hub for holding the degree wheel.

Some

additions were epoxy

bonding into the engine sump 4 large super magnets below the

transmission gears

in the path of a Mini Mania #C-AHT54 racing oil pickup.

I

used

their upgraded water pump

#GWP-187EVO with the largest stamped steel pulley I could find (much

lighter

than the aluminum version) and a two blade fan created from half of a 4

bladed

OEM fan. A #MIN500 windage tray was fitted. Swain Technology thermal

barrier

coated our piston crowns and their anti-friction coating was put on the

skirts.

Swain also coated our tappets with anti-friction material and coated

our entire

exhaust system including some heat shields I fabricated with their

“White

Lightening” compound. Swain Company was very good to work with.

Building

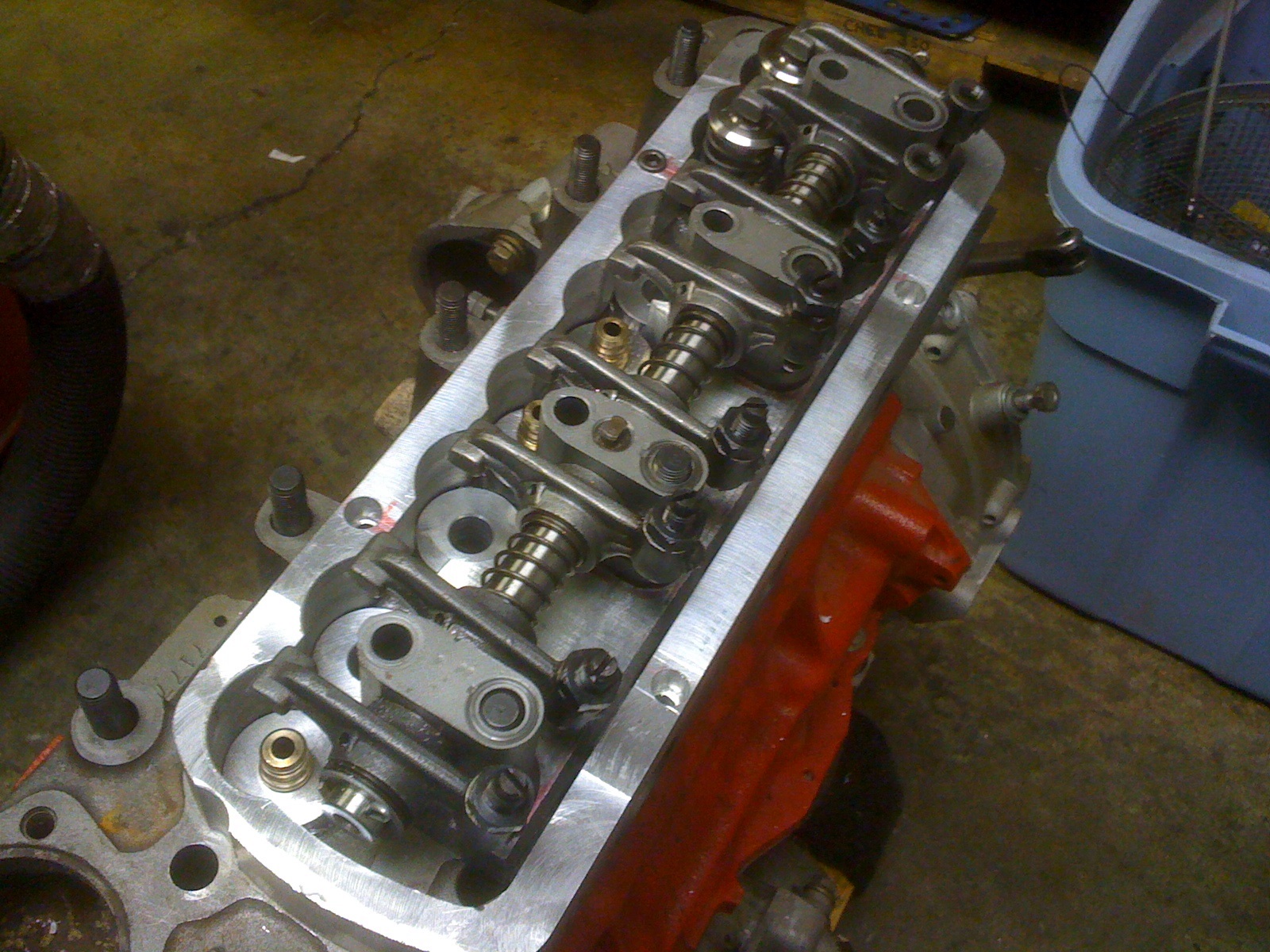

a new cylinder head

from casting # 12G940 is where the magic of this engine started.

Obtaining an

RPM range needed to win, in my opinion, was not possible with

conventional Mini

Cooper hot rod valve train parts so I looked for titanium replacements.

I

determined building a head around titanium parts which would have

smaller high

velocity ports, improved thermal dynamics and lubrication, and taller

springs

more suited to endurance stability could be a winning strategy.

SuperTech

provided Honda 5.5mm

stem diameter RSX valves, guides, lash caps, and seals. Those valves

would

nicely fit into the BMC combustion chamber after re-profiling the

chamber by

following steel patterns I made which located off the valve guides.

Shown here

are the “Longman” style valves in a Visard designed chamber

against a

non-ported casting.

Lash

caps for the Honda valves would

reduce contact loads at the rocker arm below OEM part values. With a

bit of

work Honda B/H series guides were made to fit the BMC head.

SuperTech’s BMW M3

racing valve springs were selected with complementary retainers and

locks. RSX

valves are a bit more than an inch longer than OEM Mini Cooper valves

so I

fabricated three systems of aluminum heat sinks which would fit into

that “extra”

space. One plate would fit against the

head, be restrained by rocker arm studs, allow cooling oil to pass

under and around

it, while also forming a base platform for our engines rocker arm

stands. It

has a simple drilled oil passageway for rocker arm shaft lubrication.

The

second system is formed of 8 aluminum collars press fit around the

valve guides

and tightly compressed against the head while bonding with thermally

conductive

epoxy. These strengthen the guides and conduct heat out of the guide

into the head

while holding spring seat cups. They also set installed height for the

BMW

springs. The photo below shows those parts trial fit so pushrod

clearance might

be laid out then machined in the plate first mentioned.

Necessary valve spring pressure was calculated

in Performance Trends software then set at 60lbs on the seat and 170lbs

– 180lbs

over the nose. The third system is a forged aluminum rocker arm cover

spacer

which raises the cover up allowing room for 1.5 to 1 ratio steel

rockers to

move. The valve cover spacer is notched to fit closely to the springs

so

radiated heat is conducted out of the engine to air or into engine oil. When batches of rocker arms were examined,

OEM and aftermarket, I found them erratic about placement of oil spray

holes.

Some had spray holes and some didn’t, but none sprayed at

anything useful.

There was very little room for rocker arm stands in this engine. Note

that the

stands have been profiled round on the pushrod side instead of being

squared

off. Solid shims replaced springs on the shaft itself to positively

locate the

rocker arm tip over the valve stem lash cap. It took cherry picking 3

sets of

rocker arms to get a set more or less the same. In the end, alignment

was

almost acceptable but not what I’d call “good”.

This photo shows typical misalignment that must be

corrected.

I

fabricated an oil spray bar

system pointed at the valve stem tip lash caps which will subsequently

flood

the entire rocker box area. It is installed above the rocker arm shaft

assembly. Oil is metered to the spray bar by a #56 Ford carburetor jet

held

captive below the rocker arm stand-to-shaft spray bar fitting. Spray

bar holes

are #72 drill size. Unmetered oil from the rocker arm squirt holes is

allowed

to spray wherever it ends up. I believe in operation the springs run

about half

submerged in oil acting as coolant. After

the Canadian / American Challenge National race the valve train was

inspected.

No wear or change in rockers, springs, lash caps, clearances or

pressures was

measurable.

Head

porting was minimal but

yielded flow numbers nearly as good or better than our

“Longman” head while

using slightly smaller (37mm IN and 30mm EX) titanium valves. Special

valve

seat material isn’t needed because the seats don’t get very

hot compared to

typical non-coated castings. However I installed beryllium copper seats

anyway.

The photo accurately shows there is zero extra room for the seat

installation.

The

head’s combustion chambers

and ports were thermal barrier coated by Calico Coatings, who are also

very

nice people to deal with. After all porting and modification machine

work was

completed and just moments before this head was packed to be shipped to

Calico,

several small casting pits were discovered in the roof of an intake

port which

were impossible to reach easily. While the head passed a vacuum test I

became

nervous the pits would open up to water in racing service.

I milled a large hole in the top of the head,

inspected the back inside of the castings internal surface for

corrosion damage

or a thin spot, and then installed two Lock-n-Stitch repair pins which

removed

the pit and surrounding metal (which appeared to be in fine condition)

for

security. Then I plugged the top of the head similarly to how I fixed

the block

deck. This led to re-pressure testing at

30lbs both engine block and head castings when torqued together for

cooling

system sealing integrity.

Calico

Coatings made extra

efforts to stay on my assembly time schedule by returning a finished

coating

job to us by our previously agreed date, despite my delay in shipping

to them.

They were generally “heads up” in all regards, also more

than fair by charging us

only what was originally quoted.

Calico

also coated our intake

manifold. By not allowing excessive exhaust heat to enter the head

casting,

elimination of a water bypass system is possible. Minimization of

combustion

heat to the oil via the piston was also accomplished with coatings.

Subsequent

testing indicated an external oil cooler isn’t really needed now.

* Do you dyno your engine builds? Do you know the HP, torque and

compression

ratio of the engine?

* Anything extra to add?

Some

engines I will run on an

inertial dyno at a track if it’s easy and we have time for fun.

Otherwise I let

track speed data tell me how strong an engine is. In this case other

thermodynamic testing was more important to investigate than chasing a

dyno HP

result so we ran this engine a lot doing that. I found in a half dozen

operation

cycles at 75 lbs initial oil pressure our water temperature rises from

ambient

at idle to 215 degrees F at 6000 RPM after 22 minutes run time,

stabilizing at

210 degrees F at 7000 RPM after the 23rd minute for as long as the

engine was

run thereafter. Twenty to thirty minute testing cycles simulated

typical race

duration. Oil pressure dropped to 55 lbs by the end of testing.

Pyrometer

temperature (sender about 10 inches down the center header tube from

the

exhaust header flange) peaked at 1600 degrees F. Tests were run with

the engine

installed in its chassis.

Because

time for “on track”

testing had run out we made a few hot laps around the neighborhood

where my

machine shop is located. That revealed a flat spot in acceleration

between 4500

- 5000 RPM. I felt carburetor reversion was occurring so I made

velocity stack

extenders to increase the mass of air moving forward into the

carburetor vs.

the mass of air trying to come back out from camshaft timing spit back.

The

parts shown in the photograph were epoxy cast into a two monolithic

blocks for

ease in assembly to the SU carburetor pair. This added volume of air

eliminated

the acceleration flat spot.

Early

in testing the camshaft

and tappets failed completely. Seven of the eight lobes were

essentially gone.

Two tappets had rubbed through to contact their pushrod ends. Typical

causes

were investigated and ruled out. The engine, gear box, and final drive

was

stripped and examined closely. Super magnets placed ahead of the oil

pickup saved

bearings, gears, and piston skirts nicely. Note the nearly clean oil

filter

media found in the photo below when the engine was disassembled for

failure

analysis.

Nothing

was damaged except the

cam and tappets. Because any specific cause of failure was uncertain we

elected

to forgo further metallurgical diagnosis to take a more certain

solution path

of upgrading to ceramic tappets. Ceramic tappets are compatible with

any cam

blank, require very little lubrication compared to conventional

tappets, don’t

need a break in cycle or ZPD additive, and can be moved from lobe to

lobe later

on if needed. But ceramic tappets cannot be run loose or run into valve

float.

Ceramic tappets cannot be allowed to pound freely against the camshaft

so

spring forces must be carefully selected for the RPM range an engine

will

achieve. I asked Bill Smith of

Cedarville Utah (no relation to Smith Brothers pushrod company) to make

a set

which would interface with an identical replacement camshaft but

eliminate the

BMC / Ford bucket style design allowing a set of shorter pushrods to be

re-fabricated

by Smith Brothers. Those parts eventually arrived – beautiful

parts indeed. Ceramic

tappets look like standard solid lifters but have hollow centers, are

very

light, just 3 grams heavier than the Ford 427cid bucket tappet, but

eliminated

tappet oil weight gain so their dynamic loading is much improved.

After

the engine was reassembled

oil pressure test cycling resumed attempting to learn the lowest

possible

pressure which the engine could survive on. I’d noted more

pressure drop than I

liked from “cold to hot” was occurring. After another half

dozen run cycles it

became apparent our “upgraded” race pump obtained from

usual BMC sources was

not performing well. When pressures dropped below 30lbs at 7000 RPM and

15lbs

at idle in half hour test cycles the engine was again removed and

stripped for

examination. I found both oil pump mounting bolts were loose and one of

the

screws holding the pump body together had been blown apart. We surmised

jerk

from the cams aggressive profile was overloading the pump fastening

system.

Looking inside the pump for end play (or lack of end float issues) I

found odd

wear patterns like the impellor was bouncing around. At that point I

researched

BMC oil pump history finding older models had used more retaining bolts

than

our block was drilled for. So I drilled our block for the “extra

holes”, cross

drilled fasteners for safety wire, and began to modify several new

“race pumps”

from various vendors for better sealing and retention to the block.

Additional

mounting holes would be placed where the weld material was added to

these

castings shown in the photograph.

Along

that path I found Brian

Waters Racing who sells a true BMC “A+” race pump –

it is better in every way –

so I junked what I was modifying and ordered one from him.

.

Brian’s

disassembled pump parts

are on the left side and a generic “race pump” from typical

vendors is on the

right in the following photo.

0

BWR

(Brian Waters Racing) also

sells actual ACL competition Mini Cooper crankshaft main bearings (The

Swiftune

crank uses Honda Accord CB1223-P rod bearings). So I ordered a couple

of sets

of those too. I installed main shells

providing a 360 degree oil channel. These are not to be confused with

regular

production ACL bearings sold by most vendors as the high performance

Mini

Cooper bearing.

When

the lower end of the engine

was stripped for bearing replacement after the new oil pump was

installed I was

shocked to find existing bearings were in near perfect condition after

being

run at such low pressure for as long and often as I’d been doing.

And the

ceramic tappets and cam were also in “as new” condition.

All good news

considering the National Canadian / American Challange race was just a

week

away.

However

a main cap next to the flywheel

was broken. It fell out in my hands when the ARP main studs were

loosened. It

immediately failed a magniflux inspection, then became two half caps

with a

slight tug.

We

surmised a huge clutch

shudder coupled with a very heavy OEM flywheel, which had been in the

car after

it was worked on by the other shops, had weakened the cap before a

Swiftune

Feather light unit was installed (which fixed the shudder entirely).

The

Swiftune set up removes more than 4-1/2 pounds unsupported cantilevered

weight off

the crankshaft. The remaining main caps were magnetic particle

inspected and

found to be “iffy” but I reused them anyway. The front cap

is weak because of

holes drilled into it for timing cover fastener attachment.

If I build another BMC Mini Cooper engine

I’ll

not fuss with the stock caps at all and install billet steel

replacements. In

this case another rear main cap from a different block was fitted and

the

engine re-installed for testing to resume.

I

can

mention in our testing

process Redline 50w oil performed well. We also tried Brad Penn 50w

racing oil

and Valvoline VR1. Noteworthy for consideration is considerable

quantities of Brad

Penn oil remained stuck to internal engine parts for several weeks,

long after

Redline and Valvoline had run off. With a Brian Waters Racing oil pump

and

Redline 50w oil our engine pressure regulator is set for 50lbs pressure

cold,

then doesn’t change much from that value in competition at any

RPM. I modified

our oil filtration system to use twin Fram HP6’s (or the cheaper

WIX equivalent

for break in because you just cut them open anyway) plumbed in parallel

vs. a

tiny one cup OEM filter nearly everyone else uses. I measured zero

pressure

drop across them while adding more than 2 quarts capacity to the sump

system.

Because

I measured only 15

degrees temperature drop across our oil cooler with an absolute peak

temperature of under 240 degrees F, I feel an oil cooler is not needed.

The

surface area of the filter cans has become the cooler. Removal of 10lbs

of traditional

cooler and plumbing off the left front of this Mini Cooper would be a

great

enhancement. Oil analysis by Blackstone Laboratories after the

remainder of our

test cycles and running our Nationals weekend of races found no

lubrication

deterioration vs. new oil. Blackstone then recommended 750 mile

retesting

intervals until a maximum oil life was eventually determined.

We

were very rushed moving the Mini

Cooper from my shop to the track on time for technical inspection on

the week

of the Canadian / American Challenge races. No issues were found in

scrutineering so we ran qualifying laps directly; without any

significant tune

up efforts. In testing, our engine had been timed by ear, and simply

checked to

be less than 32 degrees advanced. The SU carbs had been adjusted more

than a

year previously by looking at the plugs a few times on the old engine

set up

and monitored with my Innovate A/F gauge back then at Thunderhill. We

bolted

them to our new combination “as is” ignoring elevation and

air density changes

between the two race tracks. Our valves were checked just for changes

in clearance.

Valve clearance with ceramic tappets is .010 IN and .012 EX which could

likely

be decreased a bit. I’d retained a sensor bung in the exhaust

headers for an O2

sensor thinking I’d use my Innovate A/F ratio gauge on track at

Sonoma, but we

ran out of test dates after fixing these developmental mechanical

issues. I’d

also added a tap for measuring exhaust back pressure at the collector.

It was

zero with our headers and Flow Master muffler. From collector to

muffler is 60

inches connected by a 2 inch diameter straight pipe. We always ran the

engine

on 114 octane leaded race gas despite its low compression ratio. The

car owner

wanted to do that.

Mini

Coopers have a duct tube

going from the front of the car to an OEM heater box. When the heater

is

removed some racers use that tube to duct air to the back of the engine

where

the carburetors are. Usually the tube is just laid in there. I pushed

that

design by insulating the duct, installing a velocity stack for it

behind the

grill, installing a very tall valve cover to dam air trapped between

the engine,

hood, and firewall, and sort of bundling stuff up so air had to go

inside the

engine to vacate that space. I positioned the duct outlet with a 90

degree

plastic elbow so it blew directly into the velocity stack area. This

tube was

tested to flow 3x the air requirement of our engine at race speed. I

was

pleased to notice our “heater induction” and

“non-air-box-air-box” were working

fine when the car is on a track.

The carbs were sweating chilled water while

sitting

above a tight fitting header heat shield when the car owner came in

from doing

his qualifying laps. And I could hold my hand on the SU fuel bowls

without

burning it. At previous events there had been boiling fuel in those

areas.

Swain Tech white lightening coating worked real well for us because it

had been

applied to our headers and my custom heat shield in addition to the

entire

exhaust pipe.

In

the

photo below notice how

closely the heat shield fits the fire wall of the car. I feel it is

important for

power production to keep hot things hot where they need to be hot and

cool

things cooler everywhere else. And if you can dam a bit of air into

doing other

good things along that path – so much the better.

As raced I put a length of roll bar padding between the engine sump and front cross member sheet metal to block air coming in the grill from going down under the car. Typically this is done with a front spoiler which is illegal for stock class cars. So I lowered our car to 3 inches between the pavement and oil pan – about the height of a spoiler - then blocked the air path so it had to go up around the engine and pass the radiator to exit, or into my velocity stack “heater duct” inlet. There are no rules about gasketing the engine inside its bay similar to the way Porsche does. We also bent our mandated stock grill louvers to angle air up-and-in instead of being flat obstructions. I feel the induction system for our engine starts about 2 feet in front of the car so its grill and engine bay entry is part of its carburetion path.

As raced, our 1310cc engine had 10.2 to 1 static compression ratio and produced 97 HP in one quick dyno pull at the track on its bone stock SU H-4 carburetors. Just off the dyno I literally bumped the distributor a small nudge ahead with my fist. Gary Hubback had given the RH carb a quarter twist more jet a few weeks before after listening to the engine pull through its range and when shifted on a long straightaway. We sent the owner out to win his main event with that as a “tune up”. I’m sure there is more power to be found if we ever gave this BMC engine a proper tuning workover. On the other hand, we beat a lot of cars claiming 120+ HP in their modified classes, in addition to winning the stock class outright, so maybe it is ok as is.

However

I feel more power isn’t

the key to making this Mini Cooper run faster. Front tire traction is

the

issue. Despite a very good driver, this

engine often pulls hard enough to melt our front tires after about 5-7

full out

laps. I’m thinking how engine heat blown out the LH fender well

by the radiator

fan needs to be directed up... thereby removing about 20 degrees of

temperature

rise off that tire while converting it to modest downforce...but aero

modifications are illegal in our vintage stock class….but racing

is all about

thermodynamics and aero control…It was a frustration the rules

would bump us

out of stock class if I removed glass headlights to help vent our

fenders,

which I really wanted to do.

This article was to cover just the British

Leyland engine build, but my perspective is; all related steps and

events told

here are also part of any vintage engine build up. To make serious

advances

over what an OEM 50 year old engine did requires testing and reworking

modifications

as an integral part of the job. A build for performance in the vintage

arena

cannot be just popping some pistons in and adding an aftermarket head

with a

catalog camshaft. A vintage rebuild makes more demands of its curator

than

that. And any engine is a part of a car

that only works as well as the systems which support it. Building a

race engine

is part of development of a car, and an evolutionary stepping process.

This car

had an engine when it came into my shop and I’ll build my client

a better

version of this one if he ever wants me to do so. And I’d improve

its support

systems again even further when I install it. One of the nicest moments

at the

Canadian / American Challenge races came in a few comments made by

vendors and

a couple of other car owners, that our car was “the most legal

Mini Cooper in

stock class”. I’m not sure how true that is, but it was

received as a very

complementary observation.

I’ve also held in my hands camshaft blanks

for

revised firing order “A+” engines that have custom

crankshafts to swap firing

orders around. I know that small groups of racers in Australia, Europe,

and

Canada are also running handmade titanium valve trains of various sorts

– some

in aluminum cross flow heads. I’d guess my version of this

classic British Leyland

engine is about 7-8 years behind secret current (2017) state of the

art. But it

sure was fun for my car’s owner, buddies, and I to do what we

did. I hope you

enjoy our story.

Epilogue:

Since the National’s

in 2017 this Mini Cooper was stored waiting for the 2018 season. I

prepared it

for an event in Sonoma set for early June 2018 but various health and

other

circumstances indicated the car should be put up for sale after we ran

that

race. However, it sold very quickly so was never run. A buyer in Los

Angeles

who has no current plans to run it is the new owner. He’s more of

a

collector-racer than a racer-collector who’s deeply committed to

several new

classes of electric car racing and production.

That is the majority of what this article will cover. Lastly, please

share any

photos of the engine, its parts, and any other shop images you feel

like

including.

Done

sir,

I enjoyed writing these paragraphs. I didn’t put much effort into

formatting

the pages or reducing the size of photo files. I figure after editing

your

staff would be much better at that than I. This long story tells about

half the

work and machine operations needed to build a strong running Mini

Cooper

engine. If you wanted more data because some gaps or jumps in narrative

pop out

to you, send a few more questions and I’ll figure an addition

out. Most of these photos were electronic

chatter

between the car owner and myself as we progressed day by day so many

were taken

with a cell phone instead of a proper camera. I hope they are useful to

you. But

if there is something else you want to see let me know. I’ll look

through my

client archive file to see what may turn up.

Thanks, and I look forward to hearing from you.

Best,

Greg

Agreed, Best regards, Ladd Fowler

Final

epilogue - This engine and article gained me a nominaton for "Engine

Builder of the Year" from Engine Builder Magasine. The nomination

didn't end up with a win over 11 other builders but it was still very

nice to be considered for the honor.